Frigidaire Professional has been a strong brand for Electrolux since the early '90s. It was the first domestic appliance brand to produce appliances in stainless steel. This project was the first introduction of small domestic appliances under this brand in the United States. With our two-man design team, we partnered with our Asian suppliers to develop a range of products that kept capital costs down and provided a strong visual language that could be paired with our large major appliances.

Our first step was to educate ourselves on the products. We had the suppliers send us examples of all the platforms that were available so we could see how they were constructed, and what opportunities for improvement there might be. Below is an example of how I documented the current products.

We wanted to make sure we captured the essence of 'professional.' In collaboration with our business and design team we categorized the current market into traditional vs. progressive and mass vs. premium. We then captured images of 'professional' feeling products to help steer us during the conceptual phase.

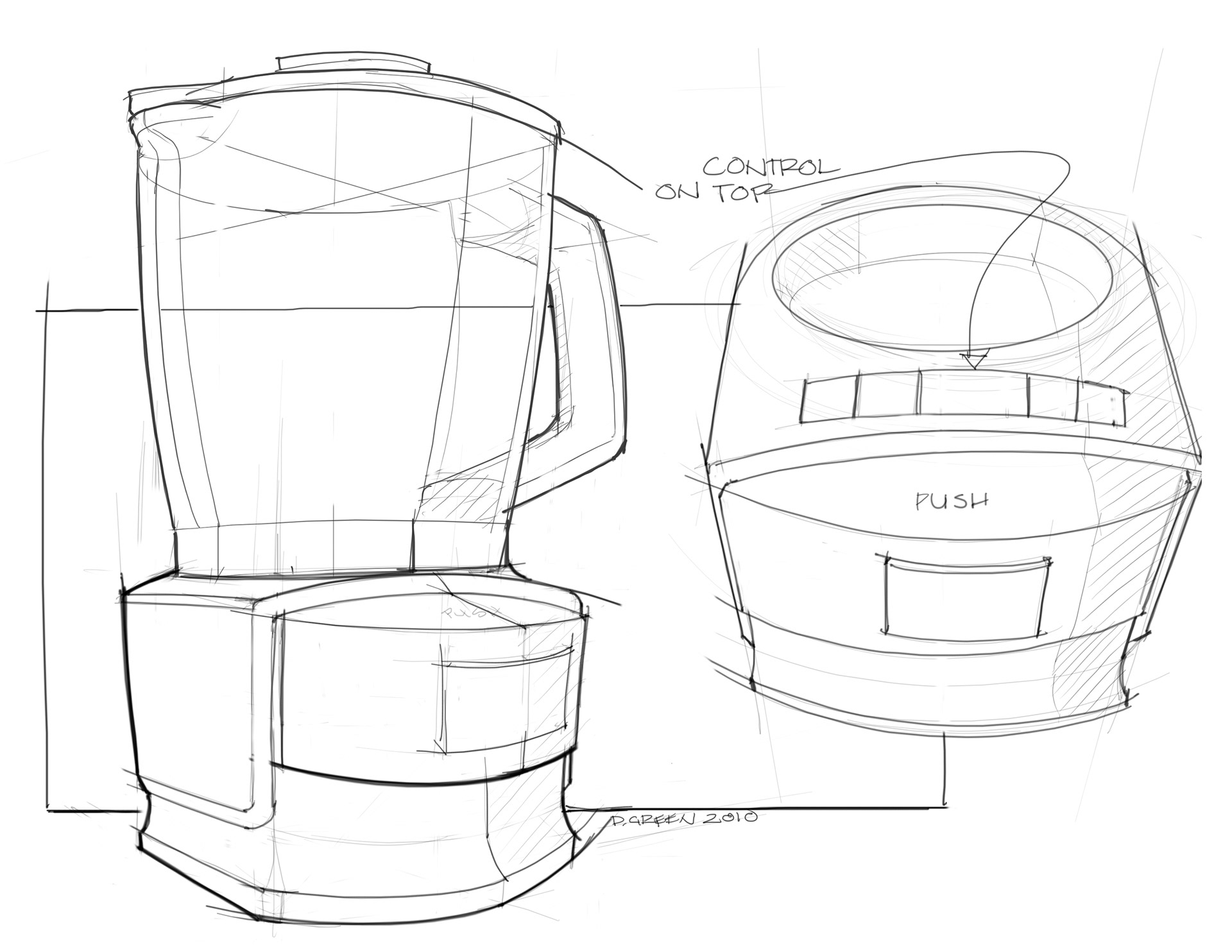

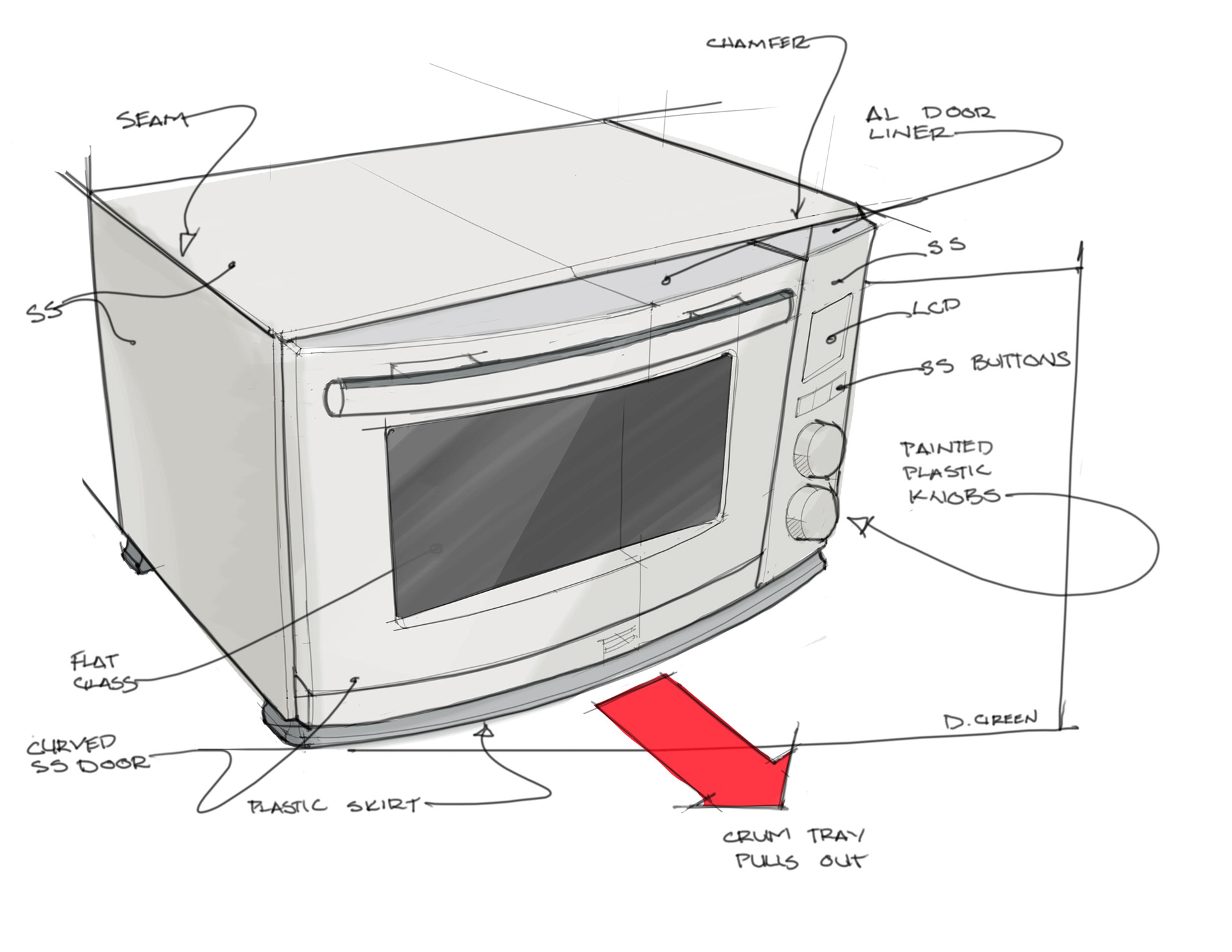

Once we were aligned on the direction, I organized a design team workshop to help bring as many ideas as possible to the table. Below are some examples of my contributions to the process.

The design direction was chosen by a panel of designers and cross-functional team members. CAD was the major focus from this point forward. I created models in SolidWorks of the coffee maker, toaster, toaster oven, and blender. We built foam study models (not shown) and refined them further based on feedback from the cross-functional team and the suppler. From there, we flew to China and spent two weeks detailing out all the products with their engineering team. We then reviewed the progress with the rest of the team back home. I was back in China two months later to finalize the CAD. They launched just six months later. Below are our final intent models built when we came back from the first China trip.